Pale ale christens Tuckahoe's brewhouse

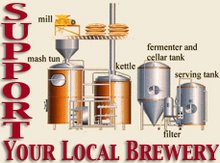

With a soundtrack of early-1970s Led Zeppelin spinning from vintage vinyl, Tuckahoe Brewing put its gas-fired brewing system through the paces on Friday, a maiden brew day aimed largely at mastering the 3-barrel setup featuring twin units of 1.5-barrel mash tuns and kettles.

With a soundtrack of early-1970s Led Zeppelin spinning from vintage vinyl, Tuckahoe Brewing put its gas-fired brewing system through the paces on Friday, a maiden brew day aimed largely at mastering the 3-barrel setup featuring twin units of 1.5-barrel mash tuns and kettles. For practically any startup brewery, inaugural batches are intended to work out the efficiencies of new brewing equipment and generally ensure the process of mashing grain, boiling wort and chilling it as it's pumped into fermenters goes smoothly and free of leaking connections or pump failures.

For practically any startup brewery, inaugural batches are intended to work out the efficiencies of new brewing equipment and generally ensure the process of mashing grain, boiling wort and chilling it as it's pumped into fermenters goes smoothly and free of leaking connections or pump failures.

But a launch brew also heralds an entry into the marketplace. And for Tuckahoe, the brew day also set the company squarely on its planned course to launch year-round and seasonal beers into the Garden State's craft beer market.

Striking a mash for a flagship American-style pale ale on the linearly arranged PsychoBrew system marked a few firsts for Matt McDevitt, who will oversee brewing operations for Tuckahoe.

A homebrewer for a decade, with the past six of that time spent sharpening his brewing skills and confidence, Matt hadn't made beer before on a high-end setup orchestrated by pumps, sensors and a control panel.

But Matt reports everything ran smoothly with the inaugural commercial brew of DC Pale Ale, a 6% ABV beer assertively dosed with Columbus, Cascade and Willamette hops. "I love hops," Matt says. DC, by the way, is a shorthand for Dennis Creek, a waterway in the part of Cape May County where Tuckahoe is located. Tuckahoe's beer names, like the accompanying seasonals Steelman Porter and Marshallville Wit, will have local themes; some brews will feature locally sourced ingredients, while some special-occasion brews will get the bomber bottle treatment (most of the beer, however, will be in the draft market).

But Matt reports everything ran smoothly with the inaugural commercial brew of DC Pale Ale, a 6% ABV beer assertively dosed with Columbus, Cascade and Willamette hops. "I love hops," Matt says. DC, by the way, is a shorthand for Dennis Creek, a waterway in the part of Cape May County where Tuckahoe is located. Tuckahoe's beer names, like the accompanying seasonals Steelman Porter and Marshallville Wit, will have local themes; some brews will feature locally sourced ingredients, while some special-occasion brews will get the bomber bottle treatment (most of the beer, however, will be in the draft market).

"As far as the equipment is concerned, everything has gone very well so far," Matt says. "I've been paying close attention to the pumps, the recirculation, just making sure the grain bed is setting, making sure nothing is getting stuck. So far, so good, just a few hiccups earlier. Also, what I've been paying attention to is the control panel; it's the first time I've ever operated this."

Prior to the inaugural brew day, only some preliminary checks had been conducted on the stainless steel brewing equipment – so new and shiny that from across the brewery you could still pick out sharp reflections of Matt and Chris Konicki, another Tuckahoe partner who helped with the mash-in on Friday.

"Three weeks ago, while I was on the phone with the manufacturer of the system," Matt says, "I ran a (test) run with just water in just one of the mash tuns, just to see the recirculation, just to set a temperature, see if it could get to the temperature, see how the regulated gas comes on an off, just to see essentially if it works."

Unlike larger brewhouse setups, the PsychoBrew system's mash tun uses an intermittently lighting gas flame to maintain a preset mash temperature, and pumps to recirculate liquid that seeps below the grain bed grate to keep the sugars developing from the mash from scorching and becoming unintentionally caramelized.

"Earlier one of the mash tuns stopped recirculating, so it was just a matter of opening the ball valve a little more," Matt says.

Founded a year ago as a partnership of Matt, Chris, Tim Hanna and Jim McAfee, Tuckahoe was licensed by state regulators just 10 days ago, making the brewery the latest startup in a very busy growth year for New Jersey's craft brewing industry. (Matt, Chris and Tim are teachers in Atlantic County; Jim is an architect who designed the brewery.)

This year alone, Tuckahoe is the fifth beer-maker to claim the mantle of "New Jersey's newest craft brewery." It's a title not lost on the crew who set up shop in Dennis Township in Cape May County and became that county's second brewery this year as well. (Cape May Brewing was licensed last spring.)

"It's a little scary and surreal," Matt says, "but I'm pretty happy and confident that after getting my feet wet and comfortable with the system, I think we can do something pretty good, and I think a lot of people will enjoy it." Located in a light industrial building shared by a fish market and a coffee roaster, Tuckahoe Brewing is tricked out with a pair of 3-barrel fermenters in the center of the brewery space. A pair of similar-sized bright beer tanks are situated in a cold box along a far wall, where an array of 60 black, polyurethane sixtels and 20 half barrels are stacked. The brewhouse is moored along an opposite wall and accessible by a low scaffold trimmed with a berm and fitted with drains and plumbing that substitute for a trench drain in the floor.

Located in a light industrial building shared by a fish market and a coffee roaster, Tuckahoe Brewing is tricked out with a pair of 3-barrel fermenters in the center of the brewery space. A pair of similar-sized bright beer tanks are situated in a cold box along a far wall, where an array of 60 black, polyurethane sixtels and 20 half barrels are stacked. The brewhouse is moored along an opposite wall and accessible by a low scaffold trimmed with a berm and fitted with drains and plumbing that substitute for a trench drain in the floor.

A flight of stairs leads to a loft office, equipped with turntable and stacks of LPs to create that ever-important soundtrack for brew days.

The brewery entrance opens to a reception area done up in a mural of the South Jersey shore from Sea Isle to Atlantic City painted by an artist friend. Brewery open houses are planned, as soon a the foursome can acquire the necessary permit for the tasting room.

Amid the brew day on Friday, as work friends and neighbors stopped by with well-wishes, Matt, 36, a new dad for the second time (his son Jack was born around start of December), paused to reflect on a parallel between his life and his father's.

"It's funny, when I was born, the same year, pretty close to my birthday, my dad opened a new photography studio," Matt says. "It's kind of interesting and cool that the same month that my son is born, I open up a business. I like that. The continuity of that is kind of cool."